■ Product Introduction

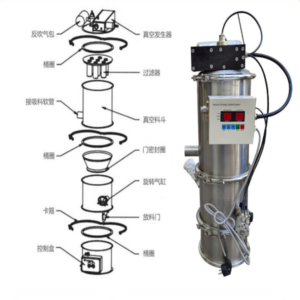

Powder or granular materials enter the buffer silo. A vibrating hopper and a metering screw are connected below the buffer silo. Material from the metering screw outlet is vacuum-suctioned into the solid-gas separation chamber of the feeder. A weighing sensor is located below the chamber. When the weighing sensor detects the set weight, it notifies the metering screw to feed at its designated speed, followed by vacuum suction. Once the set weight is reached, the entire system stops operating,and the weighed material is unloaded to the designated location.

■ Features of Product

The system is lightweight and has a small footprint, allowing for flexible placement depending on the site. It has low energy consumption, low noise, and an extremely low failure rate. Suitable for mixing single or multiple materials in a proportional manner. It offers high weighing accuracy; for batches of materials with good flow ability, the weighing ratio can be controlled to approximately 0.5%.