Fully Automated Feed Production Line: Tailored for Indonesian Feed Industry

Exclusively designed for Indonesian clients operating in the feed sector, this integrated production line comprises three screw conveyors, one ribbon mixer, a storage hopper, and a packaging machine—engineered to deliver a fully human-free, automated workflow that streamlines feed processing, boosts production speed, and ensures seamless operation throughout the entire cycle.

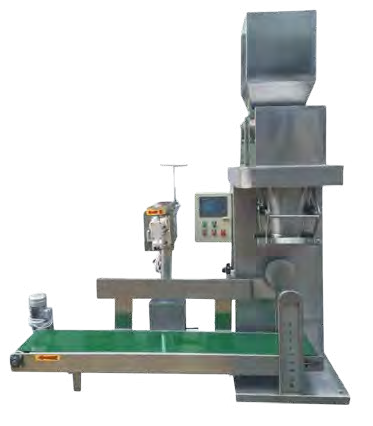

The line’s workflow is meticulously optimized for efficiency and continuity, eliminating manual intervention at every stage. The first screw conveyor precisely feeds raw materials (such as grains, protein additives, and mineral supplements) into the ribbon mixer—equipped with dual counter-rotating ribbons that ensure uniform mixing (achieving a mixing homogeneity rate of ≥95%, critical for maintaining consistent feed nutrition, a key requirement in Indonesia’s feed quality standards). Once mixing is complete, the second screw conveyor swiftly transfers the blended feed to the storage silo, which features a capacity-matched design (customizable based on client’s hourly output, typically 5 tons) to prevent material accumulation and ensure steady downstream supply. The third screw conveyor then transports the stored feed from the silo to the packaging machine, which supports variable bag sizes (25kg, 50kg, or custom specifications common in Indonesia’s feed market) with high weighing accuracy (±0.2%), meeting the industry’s strict packaging precision demands. Notably, while the subsequent stages (mixing, silo storage, packaging) are in progress, the first screw conveyor simultaneously starts feeding raw materials into the ribbon mixer for the next batch—enabling continuous batch cycling and eliminating production downtime, a game-changer for solving the traditional feed industry’s pain point of slow, disjointed processing.

Automation is the core strength of this line, driven by a smart PLC control system with an intuitive English-Indonesian bilingual HMI. Operators can easily set parameters (mixing time, feeding speed, packaging weight) with just a few clicks, monitor the entire production process in real-time (via built-in sensors for material level, mixing status, and conveyor operation), and receive automatic alerts for anomalies (e.g., material shortage, mixer overload). This not only reduces the learning curve for staff (requiring only basic training) but also minimizes human errors that often lead to feed quality inconsistencies or production delays—fully realizing the “no manual labor” advantage.

Beyond automation, the line is engineered to address Indonesia’s specific feed production needs. All equipment in contact with feed (screw conveyor liners, ribbon mixer chambers, silo inner walls) is made of food-grade 304 stainless steel, complying with Indonesia’s food safety regulations (SNI 01-3954-2008 for animal feed hygiene) and ensuring no contamination to the feed. The ribbon mixer is designed with easy-clean features (detachable access panels, smooth inner surfaces) to facilitate quick material changeovers—ideal for Indonesian feed manufacturers that often produce multiple feed types (e.g., poultry feed, aquafeed) on the same line. Additionally, the storage silo is equipped with a moisture-proof system and temperature monitoring to protect feed from Indonesia’s humid tropical climate, preventing mold growth and preserving feed quality.

In terms of production efficiency, the line significantly boosts output compared to manual or semi-automated setups: with a typical cycle time of 15–20 minutes per batch (depending on batch size), it achieves an hourly production capacity of 3–5 tons—doubling or even tripling the speed of traditional lines. The seamless integration between equipment (e.g., synchronized speed between conveyors and mixer, precise material level control in silo) eliminates bottlenecks, ensuring the entire line runs smoothly without interruptions.

This fully automated feed production line not only solves the industry’s core challenges—replacing labor-intensive manual work, improving production speed, and ensuring consistent quality—but also aligns with Indonesia’s growing demand for efficient, compliant feed manufacturing solutions. It is an ideal investment for Indonesian feed producers looking to scale operations, reduce costs, and meet the country’s strict feed safety and quality standards.