Specifically engineered for Chinese clients in the quartz sand sector, this high-performance screening system integrates a square gyratory sifter, a tumbler screener, a circular vibrating screen, and screw conveyor—designed to deliver a fully labor-free, automated, and low-maintenance multi-stage screening solution that meets the rigorous precision and high-yield demands of quartz sand processing.

The line’s workflow is seamlessly aligned with on-site quartz sand production processes, starting from the client’s existing crusher. After initial crushing, quartz sand is directly fed into the square screen—the first stage of screening, which is uniquely engineered to maximize throughput. Unlike traditional screens, the square gyratory screen features a large screening area (customizable from 2㎡ to 6㎡ based on client’s capacity needs) and a multi-layer sieve design, enabling it to handle high-volume feed rates (up to 50 tons per hour) while efficiently separating coarse impurities and oversized particles. This addresses the core requirement of Chinese quartz sand manufacturers for large-scale screening, laying a solid foundation for subsequent precision processing.

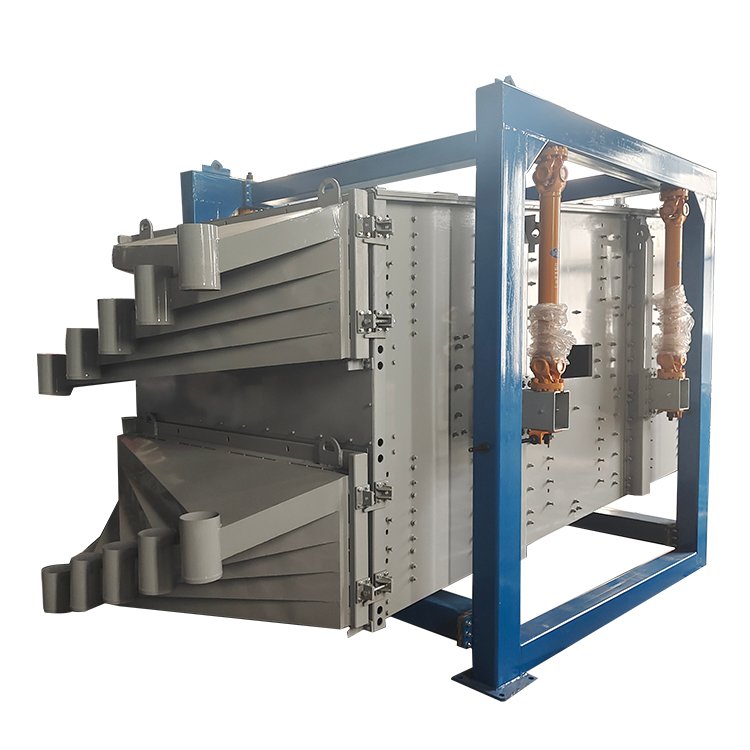

Following the first-stage screening, the pre-processed quartz sand is smoothly transferred to the tumbler screening machine via a dedicated screw conveyor. The tumbler screen adopts a high-frequency, low-amplitude vibration motion that ensures gentle yet effective separation of medium-sized particles, with adjustable sieve mesh sizes (ranging from 0.1mm to 5mm) to match different quartz sand grade requirements—common in Chinese industries such as glass manufacturing, construction aggregates, and semiconductor materials. Its enclosed structure prevents dust leakage, complying with China’s environmental protection standards (GB 16297-1996 for air pollutant emissions) and maintaining a clean workshop environment.

After the second-stage screening, the quartz sand is conveyed by another screw conveyor to the circular vibrating screen for the final precision screening. Equipped with a high-efficiency vibrating motor and a three-layer sieve (with screening efficiency ≥95%), this third stage removes fine dust and ultra-fine particles, ensuring the final quartz sand meets the client’s exact quality specifications—whether for high-purity industrial applications or general construction use. The entire multi-stage screening process is fully automated, with no manual intervention required.

A standout advantage of this line is its minimal maintenance requirement. All key components—including the sieve meshes of the three screens and the blades of the screw conveyors—are made of wear-resistant materials (such as high manganese steel and polyurethane) that withstand the abrasiveness of quartz sand, significantly extending service life. The screens feature a quick-release sieve frame design, allowing for easy mesh replacement in just 10-15 minutes without specialized tools, while the screw conveyors are equipped with self-lubricating bearings that reduce the need for frequent maintenance checks. This design drastically cuts down on downtime and maintenance costs, a critical benefit for Chinese manufacturers aiming to maximize production efficiency.

In addition to meeting high-yield and precision demands, the line is tailored to China’s industrial context. It supports flexible integration with existing crushing equipment (compatible with common crusher models in Chinese quartz sand plants), and the control system features a Chinese-English bilingual HMI for easy operation by on-site staff. Energy-saving measures—such as variable-frequency motors for all equipment and low-power vibrating systems—help reduce energy consumption by 15–20% compared to traditional screening lines, aligning with China’s national policies on energy conservation and emission reduction.

This fully automated multi-stage screening line not only solves the key challenges of the Chinese quartz sand industry—achieving large-scale production, precise grading, and low maintenance—but also provides a reliable, cost-effective solution for clients looking to upgrade their screening processes. It is an ideal investment for Chinese quartz sand manufacturers seeking to enhance competitiveness, meet strict quality standards, and adapt to the evolving demands of the domestic market.