In the rapidly evolving landscape of new energy and advanced materials, efficiency, precision, and safety are not just goals—they are imperatives. One of our project for a leading Chinese manufacturer showcases how cutting-edge automation is revolutionizing production, addressing critical industry challenges while setting new standards for intelligent manufacturing.

We are proud to have successfully designed and implemented six complete, fully automated production lines tailored specifically for the precise demands of the new energy materials sector. This turnkey solution seamlessly integrates state-of-the-art equipment to create a closed-loop, intelligent workflow from raw material handling to final packaging.

The Integrated System: A Synergy of Precision

Each line is a marvel of engineering synergy, featuring:

Vacuum Conveying Systems: Ensuring dust-free, gentle, and efficient transfer of sensitive powders, eliminating manual handling and contamination risks right from the start.

Intermediate Storage Silos: Providing buffered capacity for continuous, uninterrupted downstream processing, enhancing overall line stability.

Vibratory Screening Machines: Guaranteeing the consistent quality and uniformity of raw materials by removing impurities and agglomerates, which is crucial for final product performance.

High-Accuracy Weighing & Batching Systems: The intelligent heart of the line. These systems deliver exceptional precision in ingredient dosing, directly impacting product consistency and formulation integrity.

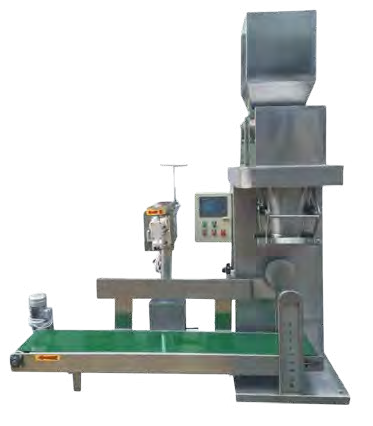

Automated Packaging Machines: Completing the process with swift, accurate, and sealed packaging, ready for storage or dispatch.

Addressing Core Industry Challenges

This project delivers transformative benefits by tackling two major pain points head-on:

Conquering the Dust Dilemma: New energy materials, often fine and reactive powders, pose significant health, safety, and product loss challenges. Our fully enclosed, vacuum-based conveying and processing system virtually eliminates dust generation. This creates a safer, cleaner working environment, protects product integrity, and minimizes material waste—a critical step towards sustainable operation.

Unlocking Intelligent, Unmanned Operation: Moving beyond basic automation, the lines embody true intelligent manufacturing. The integrated control system orchestrates every component—conveying, screening, batching, and packaging—into a synchronized, self-regulating process. This eliminates human error in weighing and mixing, ensures batch-to-batch consistency, and allows for 24/7 continuous production with minimal supervision.

Adding Color to Efficient Production

By seamlessly merging dust-free material handling with robotic precision and smart control, this solution does more than just automate—it optimizes. It ensures the highest product quality for the demanding new energy market, dramatically boosts overall equipment effectiveness (OEE), and reduces operational costs. It paints a future where production is not only faster and cleaner but also smarter and more reliable.

This installation is more than just six production lines; it’s a strategic leap forward. It empowers our client to meet the soaring demand for high-performance new energy materials with unparalleled quality control and operational agility, solidifying their competitive edge in the green technology revolution.

Is your production process ready for the next level of intelligence, precision, and cleanliness? Explore how a tailored automated solution can transform your operations.