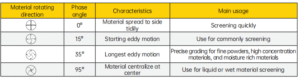

■ Working principle

The vibrating sieving is excited by a vertical electric action,because its upper and lower end weights are installed on both sides of the engine shaft, so that the rotating motion of the motor is transformed into a vertical, horizontal and inclined three-dimensional motion. By changing the phase angle between the weights at the upper and lower ends, the movement trajectory of the material on the screen surface can be changed.

■ Features

1. High efficiency, exquisite design and durability, suitable for screening any powder and viscous liquid.

2. The screen is not blocked, the powder is not flying, and the finest filtering can reach 500 meshes.

3. Impurities and coarse materials are automatically discharged, suitable for comprehensive operation.

4. No mechanical effect, easy to maintain, and can be used in single or multiple layers.

5. The operation is simple, the screen is easy to change, and it is easy to clean.

6. Small size, space saving and easy to move.

7. The contact parts of all products are made of stainless steel.

8. The screen design is unique and durable, and it only takes 3-5 minutes to change the screen.

■ Scope of application

Chemical industry: resin, industry, medicine, cosmetics, paint, Chinese medicine powder, etc

Food industry: powdered sugar, starch, salt, rice flour, milk powder, soy milk, egg powder, soy sauce,fruit juice, etc.

Metals, metallurgy and mining: aluminum powder, lead powder, copper powder, ore, alloy powder,welding rod powder, manganese dioxide,electrolytic copper powder, electromagnetic materials,

grinding powder, refractory materials, kaolin,lime, alumina, heavy carbon acid Calcium,quartz sand,etc.

Other industries: waste oil, wastewater, dyeing and finishing wastewater, paper making, additives,activated carbon, etc.