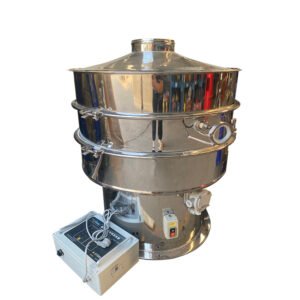

■ Product Introduction

The Trommel screener uses a specially designed screen mesh, resulting in high screening efficiency and a long service life. Its small installation inclination angle prevents screen holes from clogging easily. It features a simple structure, convenient maintenance, stable operation, low noise, and a small footprint, facilitating process layout. It can be used in chemical, coking plants, mines, power plants,building materials, and metallurgical industries. The drum assembly is installed at an incline on the frame. The exterior is sealed with a protective enclosure to prevent contamination.

■ Working Principle and Structural Features

The motor connects the reducer to the drum assembly via a coupling, driving the drum assembly to rotate around its axis. The rotary drum screen utilizes a mechanical method, with several parallel screen bars forming holes to create the screen surface. After the material is placed into the drum assembly, the inclination and rotation of the drum cause the material to tumble and roll, passing through the screens of different mesh sizes one by one. Material stuck in the screen holes is also ejected, preventing clogging. It adopts a special screen, which has high screening efficiency and long service life; small installation tilt angle, screen holes are not easy to clog; simple structure, easy maintenance; stable operation and low noise; small space occupation, which is convenient for process layout.