For professionals in the aluminum powder industry, achieving efficient, high-precision screening of fine and ultra-fine powders has always been a significant challenge.

Why Fine Aluminum Powder is a Screening Challenge?

Aluminum powder, especially grades used for metallurgy, coatings, and additive manufacturing, often exhibits characteristics that make it particularly difficult to screen:

1.High Static Charge

2.Light Density & Low Mass:

3.Near-Size blogging”.

Traditional methods like using rubber balls or slider rings to clean the mesh can be ineffective for these powders and risk contaminating the product.

How the Ultrasonic System Transforms Screening?

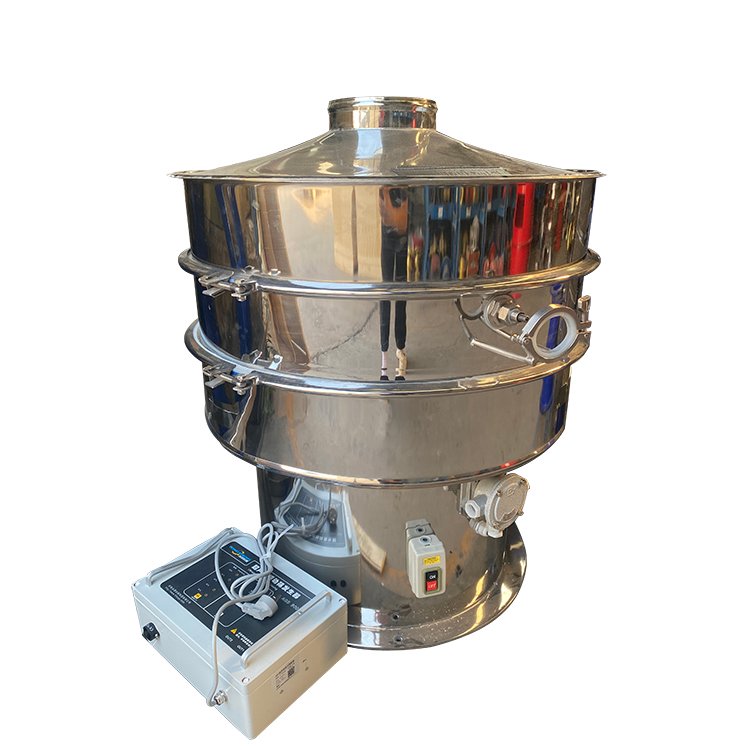

Here’s the core of its innovation: the ultrasonic vibration screen superimposes a high-frequency, low-amplitude mechanical vibration directly onto the screen mesh. This dual-vibration action is the key to unlocking performance.

The Dual-Action Advantage:

1.Breaking Down Forces:It neutralizes static charges, breaks up agglomerates, and keeps particles from sticking.

2.Promoting Flow: This maintains the screen’s Effective Open Area at a maximum throughout the entire operation.

3.Eliminate Clogging & Boost Output:This directly translates to higher throughput and consistent processing rates, with some applications reporting potential output increases of up to 10 times.

4.Achieve Superior Precision: allowing for reliable grading down to 400 mesh (37µm) and even finer.

This technology is highly recommended if your operations involve:

1.Fine and ultra-fine aluminum, alumina, or alloy powders (e.g., for PM, 3D printing, pigments).

2.Powders with strong adhesive properties, high static charge, or low bulk density.

3.Requirements for high-precision grading with consistent quality.

Conclusion

For the aluminum powder industry, where product consistency and operational efficiency are critical, overcoming the sieve blinding challenge is no longer a matter of compromise. Ultrasonic sieve cleaning technology provides a proven, elegant solution. By seamlessly combining macro-material handling with micro-particle control, it unlocks higher throughput, superior quality, and a smoother production flow.

Have you encountered specific challenges with screening fine aluminum powders like agglomeration or low yield? Feel free to share your experience or ask questions about how ultrasonic technology can be applied to different powder grades and production goals.

For more questions please contact us.

Zinplow Machinery

WhatsApp:+8613803804323

Email:wendy1993221@gmail.com